From Farm to Bottle: The Journey of Fresh Harvested Chiles.

Alexis Pola PelaezShare

When you savor the fiery kick of your favorite hot sauce, have you ever wondered about the journey those vibrant chiles took to reach your table? The process of transforming fresh, harvested chiles into authentic natural hot sauce is a fascinating one, filled with careful cultivation, precise harvesting, and meticulous production. This blog post takes you on a journey from the sun-soaked fields of Mexico to the bottle of hot sauce in your pantry.

The Origins: Cultivating Chiles in Mexico

Mexico is renowned for its rich agricultural heritage, especially when it comes to growing chiles. The climate and soil conditions in various regions of Mexico provide the perfect environment for cultivating a variety of chile peppers, including habanero, jalapeño, and chipotle.

Habanero

Habaneros are one of the hottest chile peppers, known for their intense heat and fruity flavor. They are primarily grown in the Yucatán Peninsula, where the warm climate and fertile soil produce chiles with exceptional quality.

Jalapeño

Jalapeños are beloved for their moderate heat and versatility. These chiles are mainly grown in the states of Veracruz and Chihuahua. The ideal growing conditions in these regions ensure that jalapeños develop their distinctive flavor and heat.

Chipotle

Chipotle chiles are actually smoked and dried jalapeños. The process of making chipotle begins with growing the jalapeño peppers until they reach their peak ripeness. Once harvested, they are smoke-dried to create the rich, smoky flavor that chipotle is famous for.

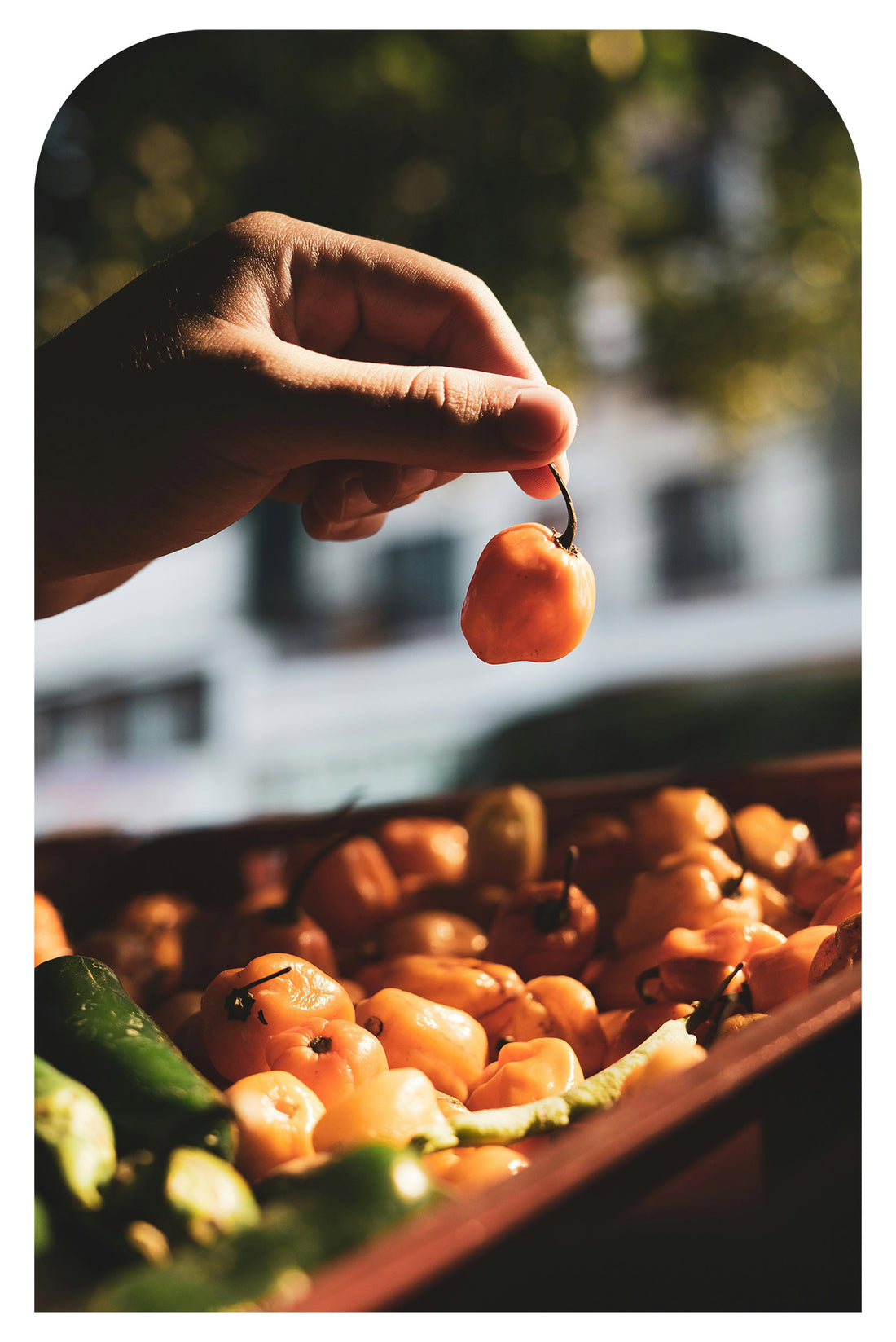

Harvesting: Picking the Perfect Chiles

The harvesting process is crucial in ensuring the quality of the chiles. Farmers carefully monitor their crops, waiting for the perfect moment when the chiles have reached optimal ripeness. This is when they have the best flavor, color, and heat level.

-

Habanero Harvesting: Habaneros are picked when they turn a vibrant orange or red, indicating they are fully ripe. Skilled laborers handpick the chiles to avoid damaging the delicate fruits.

-

Jalapeño Harvesting: Jalapeños are harvested when they are a deep green or, in some cases, red. They are picked by hand to ensure that only the best chiles make it to the next stage.

-

Chipotle Harvesting: The process for chipotle begins with harvesting ripe red jalapeños. After picking, these jalapeños are transported to smoking facilities where they undergo the drying and smoking process.

Processing: From Fresh Chiles to Hot Sauce Ingredients

Once harvested, the chiles are quickly transported to processing facilities to maintain their freshness. Here, they undergo several steps to transform into hot sauce ingredients.

Cleaning and Sorting

The first step is cleaning the chiles to remove any dirt or debris. They are then sorted to ensure that only the highest quality chiles are used. This step is vital to maintain the consistency and quality of the final product.

Fermentation (Optional)

For some hot sauces, the chiles are fermented to develop complex flavors. This process involves placing the chiles in barrels with salt and allowing them to ferment for several weeks. Fermentation not only enhances the flavor but also adds beneficial probiotics to the hot sauce.

Blending and Cooking

The chiles are then blended with other natural ingredients, such as vinegar, garlic, and spices, to create the hot sauce. This mixture is cooked to meld the flavors together and to ensure the sauce has the right consistency. The exact recipe and cooking process can vary depending on the desired flavor profile and heat level.

Bottling: Packaging the Hot Sauce

After the hot sauce is cooked and cooled, it is ready for bottling. This step involves several key processes to ensure that the hot sauce is safely packaged and ready for distribution.

Sterilization

Bottles and caps are sterilized to ensure that the hot sauce remains fresh and safe for consumption. This step is crucial in preventing any contamination that could spoil the product.

Filling

The hot sauce is then poured into bottles using automated filling machines. This ensures that each bottle contains the exact right amount of sauce. The bottles are immediately sealed to preserve the flavor and freshness.

Labeling and Packaging

Finally, the bottles are labeled and packaged for shipment. Labels often include information about the ingredients, origin, and heat level of the hot sauce. The packaged bottles are then ready to be distributed to stores and customers worldwide.

Conclusion

The journey of fresh harvested chiles from Mexico to becoming authentic natural hot sauce is a meticulous and fascinating process. From the careful cultivation and harvesting of habanero, jalapeño, and chipotle chiles to the precise processing and bottling, every step is designed to preserve the unique flavors and heat of the chiles. The result is a delicious, natural hot sauce that brings the vibrant taste of Mexico to your table. Next time you enjoy a splash of hot sauce, you'll appreciate the incredible journey it took to get there.